When designing a commercial or public space, the security grille is often left as an afterthought. But because Dynamic Closures offers so many different creative options, that’s not actually a problem. Architects who haven’t worked with us before are often delighted to realize just how well our doors can fit with their vision for a space.

That being said, there’s an ideal way to plan out a side folding security grille. Follow the steps below, and you’ll be able to accurately communicate what you want to our manufacturing team.

This guide has three parts:

Planning Steps

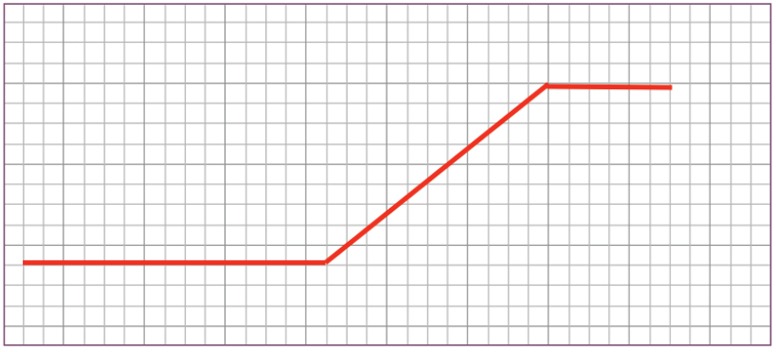

Step 1 – Track Line

Lay out the desired track line. Use straight lines, curves or a combination of both. There is no limit to the overall length of a side folding door.

Creating Curves

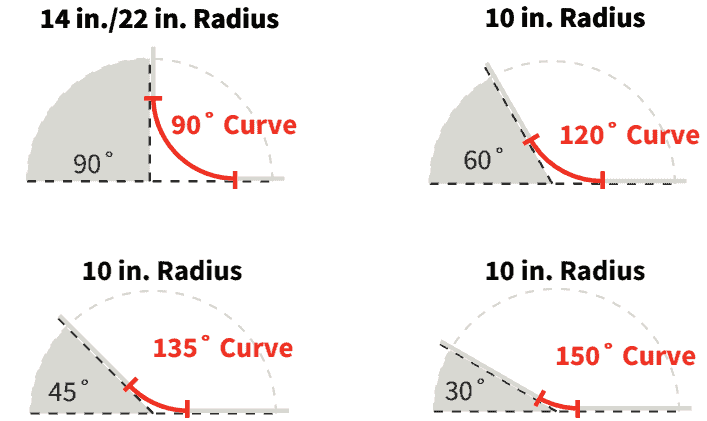

We have four types of curves that are always in stock:

Constraints:

- Radius must be at least 10” or greater.

- Angle must be at least 90° or greater.

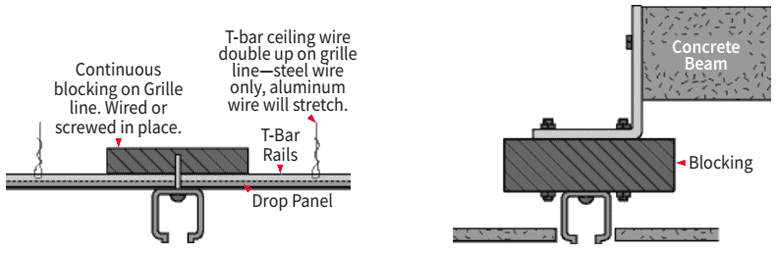

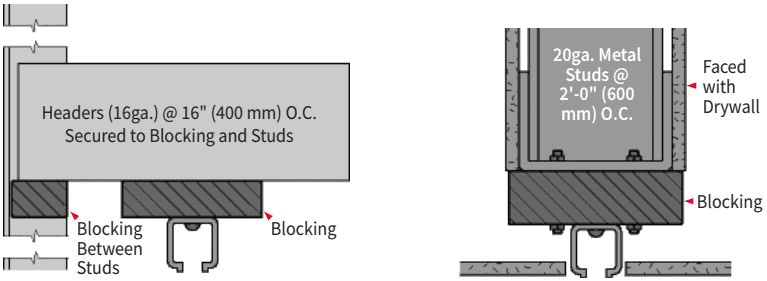

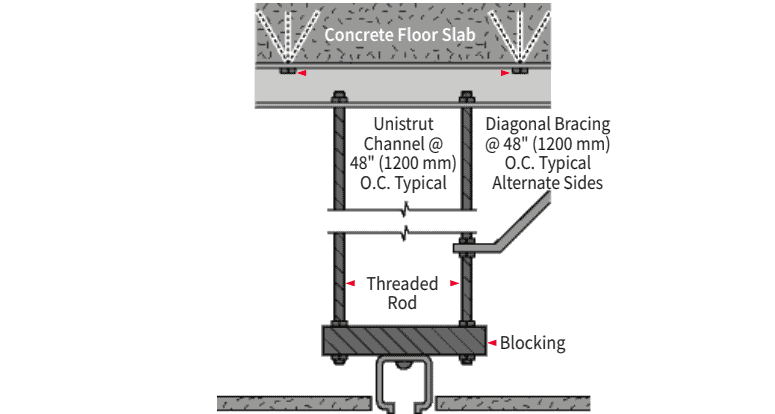

Step 2 – Header Support

The header must support the weight of the side folding door along the entire track line (see “Model Technical Specifications” chart at the bottom of this page for load requirements).

Header Examples

Step 3 – Stacking And Storage

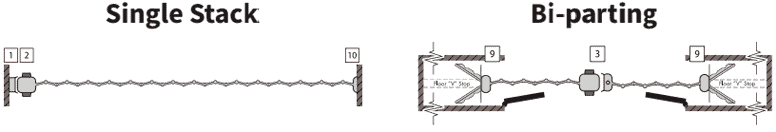

Determine where the side folding door will stack. It can stack at one end (single stack), or the side folding door can split into two and stack at each end (bi-part). Very wide doors can have more than one set of bi-parts – see Step 5 below for more details.

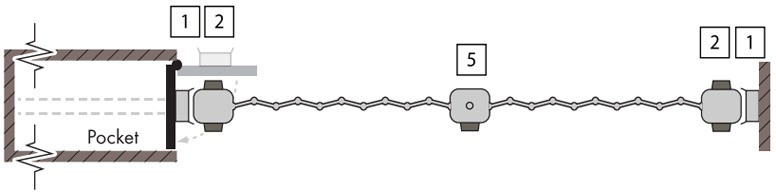

The stacked curtain can remain in the opening or in a storage pocket. Your choice will affect your end post selection.

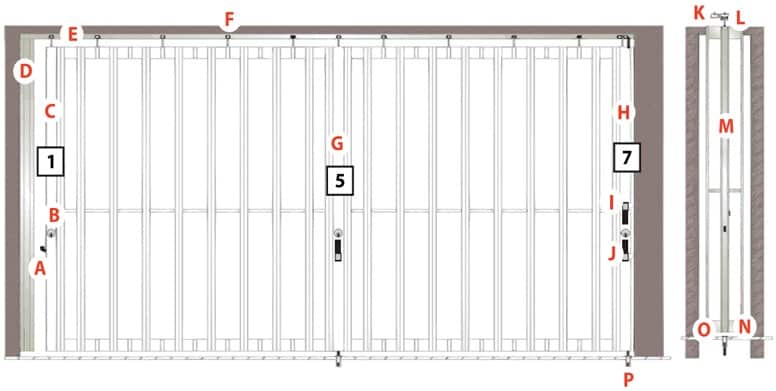

Note: for number definitions, please refer to the Side Folding Curtain diagram in the Resources section below.

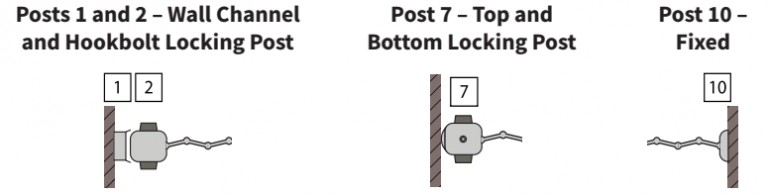

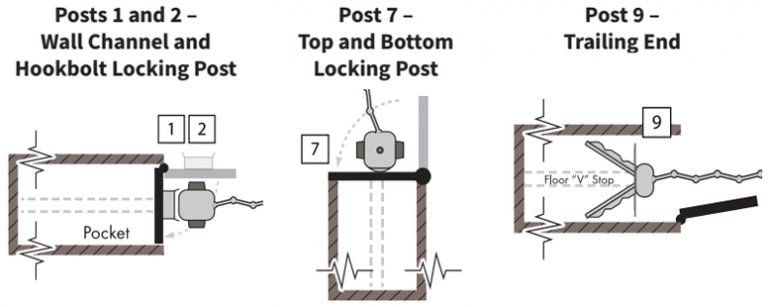

Step 4 – Choose End Posts

Single stack configurations require at least 1 locking end post such as Post 1 and 2, or Post 7 (see below).

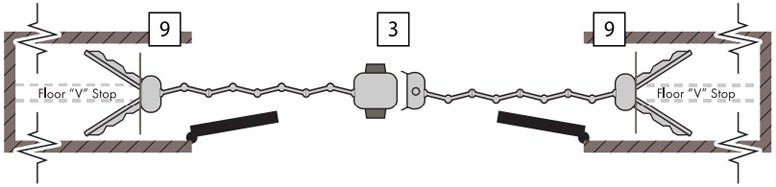

Bi-parting post have 2 stacks, and DO NOT require a locking end post.

Stack in Opening

Stack in Storage Pocket

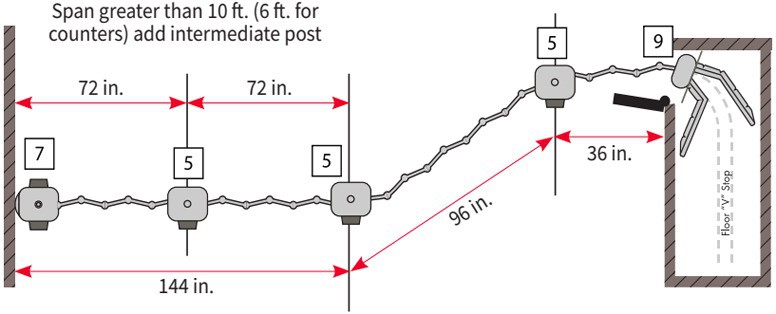

Step 5 – Plan Spacing Of Intermediate And Bi-Parting Posts

Place an intermediate post at or near the apex of each curve.

Spans between intermediate posts cannot exceed 10 feet on full height doors or 6 feet for counter doors. Place intermediate posts at required intervals.

For large doors, one bi-part is added for every 30 feet of curtain. If possible, replace an intermediate for a bi-part.

Free Specifications Verification

We provide a free review of your plans and specifications to help ensure best results.

Contact our customer support experts – they can also help guide you to door models that may work best for your needs and aesthetic.

Call 1-800-663-4599 Monday to Friday, 8AM – 5PM Eastern.

Side Folding Sample Layouts

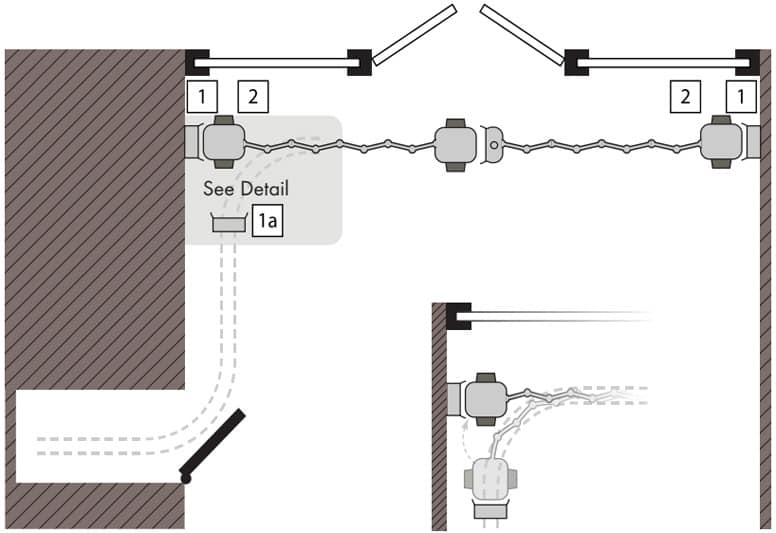

Bi-Part / Pocket Both Sides

A straightforward layout that uses two pockets to hide the stack once the curtain has been opened.

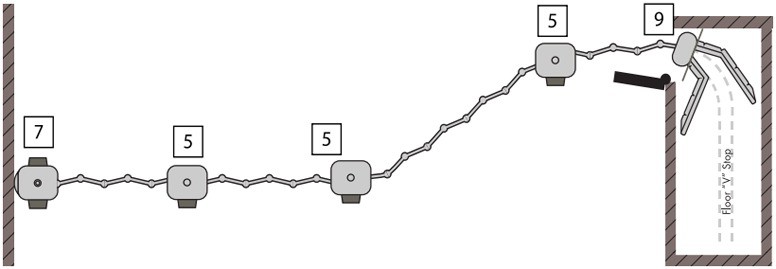

Single Stack Into Pocket

A straightforward layout that uses a single pocket area to hide the stack once the curtain has been opened.

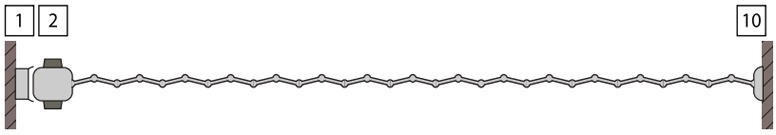

Stack Between Jambs

A simple, no-nonsense layout design ideal for when space is at premium and creating a pocket area is not possible.

“S” Curve (2-135° Curves) With Single Stack Into 90° Pocket

Dual Track

An innovative layout for use when minimal pocket depth is available.

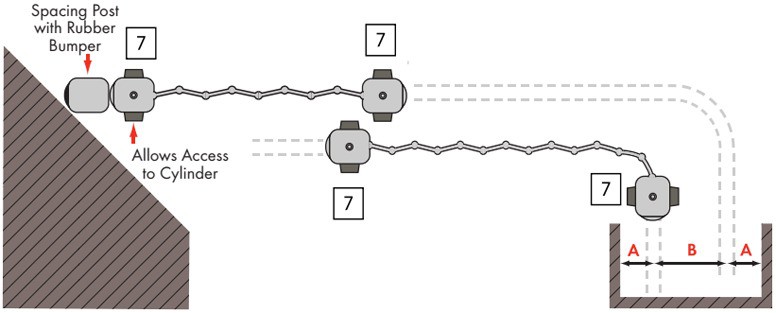

Remote Stack With Caddy

An advanced system that stores the curtain in a remote area removed from the entrance.

Caddy System Detail

Lead Post (2) without trolley assembly swings and engages Wall Channel (1). Travelling Wall Channel with Trolley (1a) transports Lead Post (2) back to pocket.

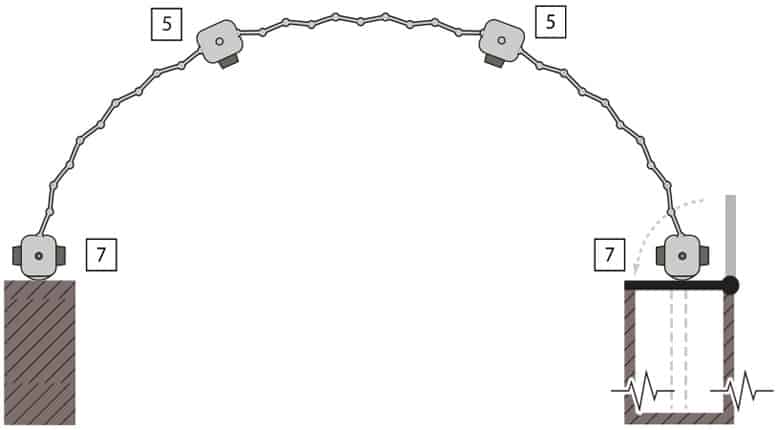

Special Radius Curve

An advanced layout for store and office designs that requires a more rounded solution.

Planning Resources

Here are some tools and specs that will help in your planning.

Guide To Post Types

This guide includes use cases and diagrams.

Calculators

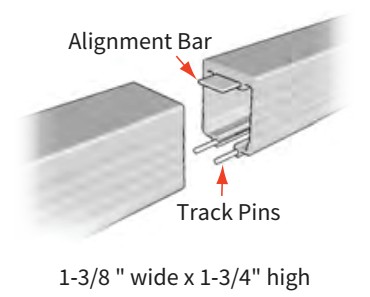

Track Dimensions

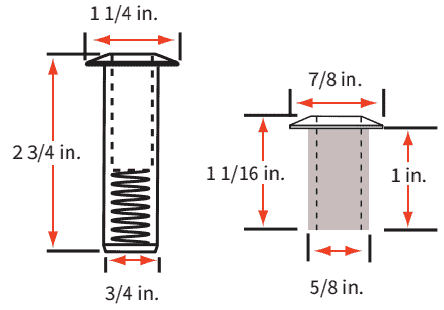

Dropbolt And Dropbolt Socket Dimensions

In-Stock Curve Details

Outstanding layout designs and thoughtful details are easily achieved with four stock curves.

| Radius | Curve | Curve Length |

| 10 in. | 120° | 10-1/2 in. |

| 135° | 7-15/16 in. | |

| 150° | 5-1/4 in. | |

| 14 in. | 90° | 22 in. |

| 22 in. | 90° | 34-1/2 in. |

More Side Folding Door Product Options

Read all about the options for every side folding door we carry. These pages include color options, specs and a photo gallery. View side folding security doors information.Side Folding Curtain Diagram

- A = Hook Bolt

- B =Keyed Cylinder Lock

- C = Lead Locking Post

- D = Full Height Wall Channel

- E = Track

- F = Trolleys

- G = Intermediate Post

- H = Top and Bottom Locking Post

- I = Shoot Bolt Knob

- J = Drop Bolt Knob

- K = Header Stop

- L = Standard Non Adjustable Hanger.

- Top of Curtain to Bottom of Track……..1 1/2 in.

- M = Minimum Clear Pocket Width

- Slim Line…………………….5 in.

- Elite…………………….8 in.

- N = Bottom of Curtain to:

- FFL……………………….1 1/4 in.

- Counter …………………..3/4 in.

- O = Drop Bolt

- P = Drop Bolt Socket

Technical Specifications Chart For All Models

| Model | Series | Material | Hinge Type | Pocket Width | Load Req. | Curtain Stack Ratio |

SL 12 CS, SL 525 CS | Slim Line | Poly/Alum | 1 Piece Cont. | 5 in. | 1.80 lbs per ft² | 10% |

| SL AG CS, SL AG PC, SL AG PS | Slim Line | Poly/Alum | 1 Piece Cont. | 5 in. | 2.00 lbs per ft² | 10% |

| SL 154 | Slim Line | Aluminum | Rod/Link | 5 in. | 1.00 lbs per ft² | 12% |

| SL OPAQUE | Slim Line | Aluminum | 1 Piece Cont. | 5 in. | 2.20 lbs per ft² | 10% |

| SL PARAVENT | Slim Line | Perf Alum | 1 Piece Cont. | 5 in. | 1.80 lbs per ft² | 10% |

| SL PRESTIGE | Slim Line | Polycarbonate | 1 Piece Cont. | 5 in. | 1.60 lbs per ft² | 10% |

| EZ 12 CS, EZ 525 CS | EZ | Poly/Alum | 1 Piece Cont. | 5 in. | 1.80 lbs per ft² | 10% |

| EZ AG CS, EZ AG PC, EZ AG PS | EZ | Poly/Alum | 1 Piece Cont. | 5 in. | 2.00 lbs per ft² | 10% |

| EZ GRILLE | EZ | Poly/Alum | Rod/Link | 5 in. | 1.00 lbs per ft² | 12% |

| EZ OPAQUE | EZ | Aluminum | 1 Piece Cont. | 5 in. | 2.20 lbs per ft² | 10% |

| EZ PARAVENT | EZ | Perf Alum | 1 Piece Cont. | 5 in. | 1.80 lbs per ft² | 10% |

| EZ PRESTIGE | EZ | Polycarbonate | 1 Piece Cont. | 5 in. | 1.60 lbs per ft² | 10% |

| EL OPAQUE | Elite | Aluminum | 1 Piece Cont. | 8 in. | 1.75 lbs per ft² | 6% |

| EL PARAVENT | Elite | Aluminum Perf | 1 Piece Cont. | 8 in. | 1.15 lbs per ft² | 6% |

| EL PRESTIGE | Elite | Polycarbonate | 1 Piece Cont. | 8 in. | 1.25 lbs per ft² | 6% |

| EL 126 B, EL 126 S | Elite | Aluminum | Rod/Link | 8 in. | 1.15 lbs per ft² | 8% |

| EL AG, EL 12, EL 525 | Elite | Aluminum | Rod/Link | 8 in. | 1.45 lbs per ft² | 8% |

Downloads Library

Get access to brochures, drawings, installation guides, specs and layouts in our downloads area.

Got a Question?

Got a question or need support?

Call us at 1-800-663-4599

Download our BAS Guide

Learn how building automation systems can make client goals achievable – especially when integrated with Dynamic Closures maglock-enabled doors.